By John Rexroad

Retooling is nothing new at Pucuda Leading Edge. We are constantly reinventing things for an improved future.  During the COVID-19 pandemic, we just naturally shifted gears to address this challenge and be part of the solution.

During the COVID-19 pandemic, we just naturally shifted gears to address this challenge and be part of the solution.

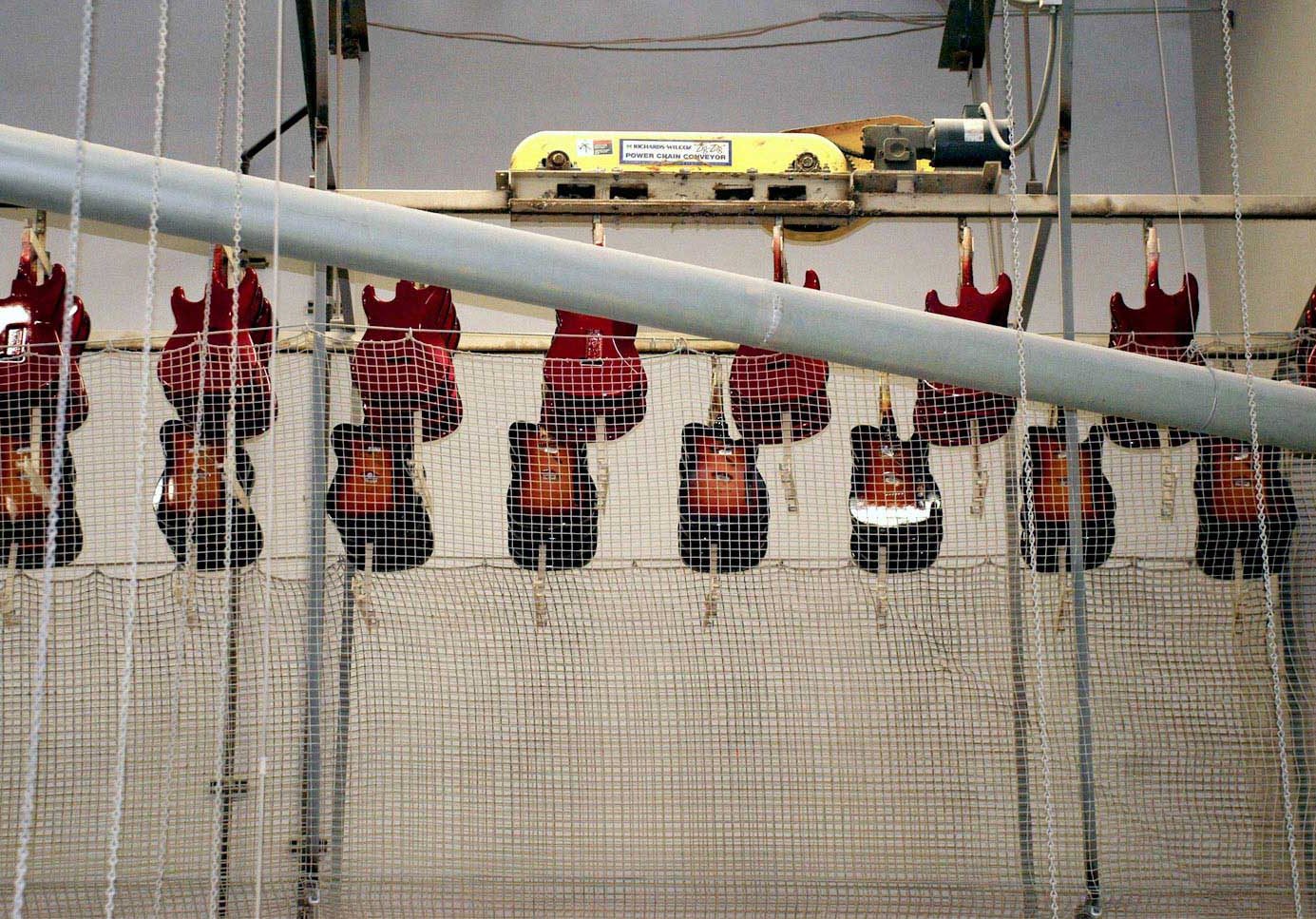

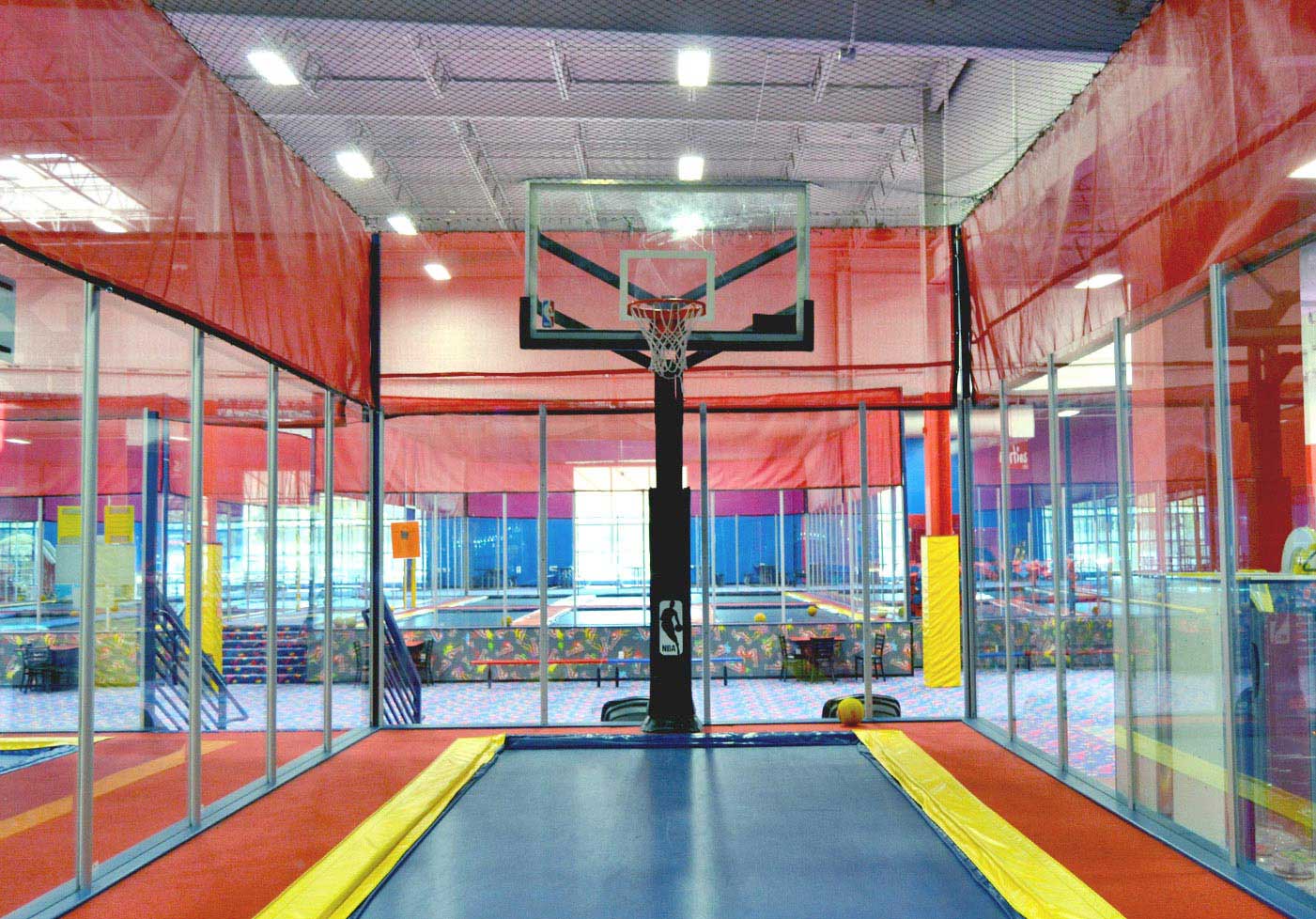

It’s important to understand how I view our role in industry and society. Worker and public safety have always been paramount for me and my company. We focus on it through an ongoing commitment to developing the most advanced and innovative safety netting as well as engineering solutions.

Early on in the pandemic, because of my work with ASTM International and safety, which is meeting a variety of needs, it was clear to me that masks for the public were going to be a necessity. Decades of experience protecting the public and providing passive safety systems made me realize that masks for the public and businesses would be vital and necessary.

I used my resources to gather information at many levels and tied with engineering know-how and common sense, started a mission that’s gone beyond retooling. To my thinking, simply “retooling” in a pandemic is changing something that exists through modification, but that was not going to meet the need and demand I saw and still know is out there.

Other Curves to Flatten

When you hear “flattening the curve” they talk about reducing pressure on hospitals and the healthcare system. I think of “flattening the curve” in a much broader way. There are many other factors which need flattening which include:

- The drain on masks being diverted from hospitals and first responders because the public is buying them.

- The cost associated with that supply which rises due to the public being willing to pay a higher price, and the greater demand for supply.

- The public and businesses needing to be prepared for a reopening of communities, states and a nation.

- Being prepared by having a washable mask that lasts longer than a day or hours.

- The unhealthy conditions being created by reusing a mask intended for disposable single-use.

- The vertically increasing line of damage to the environment caused by disposable masks.

- A scalable supply of mask manufacturing in the United States.

- Information made available that is not slanted to sell a product or push an agenda.

- Long-lasting masks that a family can afford when finances are stretched.

- Helping those in need with a donation system in place for donating masks.

That is the retooling and beyond this is really all about. We built a new business model and launched Masks For Citizens with its own website MasksForCitizens.com. This endeavor was a lot more extensive than simply moving, modifying, or just using a part of our resources. It involved tying all of the parts together. Question one was, can I do a scalable method of manufacturing, and from what materials, etc.? How do I make it available to the public and business, and the communities when there is a confusing sea of misinformation, greed, and good intention out there? Part of our story was recently published by Authority Magazine in the article “Heroes of the COVID Crisis…”

Breaking Down Barriers to Progress

Breaking Down Barriers to Progress

I hit nothing but blockades when starting, and the state was the largest blockade of all. My chances of supplying hospitals, never mind the public, would have been a much easier path. That path did nothing for the current and coming issues. In my view it would have been the selfish path. Nothing wrong with business watching out for themselves, but for me I would be failing a fundamental core principle of helping others in the process.

The masks needed to be well-thought-out, and designed to eliminate as many possible issues as possible. The mask needed to be the one I would wear and my wife on immune suppression medication after her kidney transplant would also wear. I choose not the best material for my bottom line, but the worst for my bottom line, because it was the one science was pointing to. I choose 100% cotton, and I chose to do 3 layers, not 2 layers. All these considerations added costs in both material and production.

To get beyond my small voice I hired a Public Relations firm, not to promote me, but what I have available for the public. I built an e-commerce website that could handle any amount of traffic. I made a commitment not to quit or fail my employees or others. I ran the production and donated thousands of masks before I sold one. What was important to me was to bring my workers back.

My vision was to look forward and analyze what possibilities and likelihoods existed in the future. All of the indicators were out there as they are today. I saw that a company taking the CARES Payroll Protection funds would only have 8 weeks and was required to spend it during those 8 weeks and that it required funding payroll beyond that 8 weeks to make the loans forgivable. I saw that masks were going to be needed by the public when many were saying “masks don’t work.” I saw that the public was going to increase the drain on the vital and necessary supply of masks so desperately needed by our essential workers. I saw that increasing demand from hospitals, states, and the public could cause escalating prices.

The Need to Spread the Word

The first flood of orders came after the Hartford Courant did a story. At first, the orders began Friday, April 17th like opening a floodgate on an overflowing lake. Not just the number of orders but the amount of masks per order. That  Friday, April 17, I realized it was a flood of need, and I needed to meet that challenge. That same night I was virtually shopping, buying thousands of yards of 100% cotton fabric, and I received it Saturday night. That Monday, April 20th I bought 24 new commercial sewing machines, set up stacked cutting and by that Tuesday, April 21st I had 4 of the new machines in operation with new sewers. By Friday of that week, I had the full line in operation, which meant hiring new employees, tens of thousands of dollars invested, and taking great risks. Orders have leveled off or slowed as other supplies from China flood the market, but we are working hard to get the word out in media about the quality of our 100% cotton, washable masks made in Connecticut.

Friday, April 17, I realized it was a flood of need, and I needed to meet that challenge. That same night I was virtually shopping, buying thousands of yards of 100% cotton fabric, and I received it Saturday night. That Monday, April 20th I bought 24 new commercial sewing machines, set up stacked cutting and by that Tuesday, April 21st I had 4 of the new machines in operation with new sewers. By Friday of that week, I had the full line in operation, which meant hiring new employees, tens of thousands of dollars invested, and taking great risks. Orders have leveled off or slowed as other supplies from China flood the market, but we are working hard to get the word out in media about the quality of our 100% cotton, washable masks made in Connecticut.

All this upfront investment means not just meeting the current demand but the ongoing and future projected demand. That is what we do during a pandemic – take risks and actions. We remain committed to using drive, determination and decades of experience to keep “retooling” for whatever the next challenge may be. That’s how a visionary company makes things happen.

If you have questions about ordering or donating masks to an organization, feel free to call us at 800-241-7330.