June was National Safety Month, recently reminding us that all workers should have the expectation of safely leaving their job after a day’s work. On the job, everyone needs to feel the confidence of performing tasks without fear of injury. Excluding military, police, fire and other emergency workers, no employee should expect openly hazardous or deadly situations at work. Even military and first responders take robust safety measures to protect themselves against the known risks they face due to the nature of their work. (Gratitude for their sacrifices and brave service comes to mind here.)

Workplace safety is a very big deal!

According to OSHA, American businesses spend $170 billion a year on costs associated with occupational injuries and illnesses. The value of a single human life cannot be measured, so the first imperative in designing a workplace or preparing a job site is eliminating or minimizing potential hazards. Installing the right safety equipment and materials along with proper training should be the first order of business when sending crews to any jobsite. It’s every company’s duty to make certain that all employees feel safe and secure while serving the company, its customers, or the public.

On the surface, it may seem burdensome for businesses to put a major emphasis on costly safety measures or fully comply with strict safety regulations. After all, “Back in the old days they didn’t have all these modern safety requirements and things got done anyway!” …says the guy who ignores the morbid statistics of accidents and illnesses during the Industrial Revolution and other periods leading up to the 21st Century.

Today the extra burden is on companies that forego safety regulations for the sake of profit or expediency. Such businesses expose not only their employees to greater risk but put their future in jeopardy of heavy fines and lawsuits as well as public relations nightmares. Workplace safety might be a significant cost of doing business but just think about the cost of NOT doing business!

The Smart Money is on Safety

A safety culture in your workplaces and jobsites provides many positive returns in addition to reductions in injury and saved lives. Put simply, safety and wellness add value to your business. Implementing a strong safety culture in your company will:

- Save money by lowering injury downtime and qualifying for insurance discounts.

- Help prevent injury and death.

- Lower exposure to lawsuits

- Improve productivity through higher employee morale.

- Demonstrate care for employees’ well-being.

- Set good safety examples in the community.

As manufacturers of safety products ourselves we can wholeheartedly agree with a quote from a manufacturing representative found on the OSHA website: “We can’t make a quality product with an unsafe process.” Well-protected workers focus better on their tasks which includes all aspects of quality control throughout each step of the manufacturing process, whether it be fabricating a part or constructing an entire building. The National Safety Council offers a comprehensive array of safety compliance and training materials for organizations of all types and sizes. A visit to their workplace safety page will lead you to some helpful resources.

“Catch me when I’m falling…”

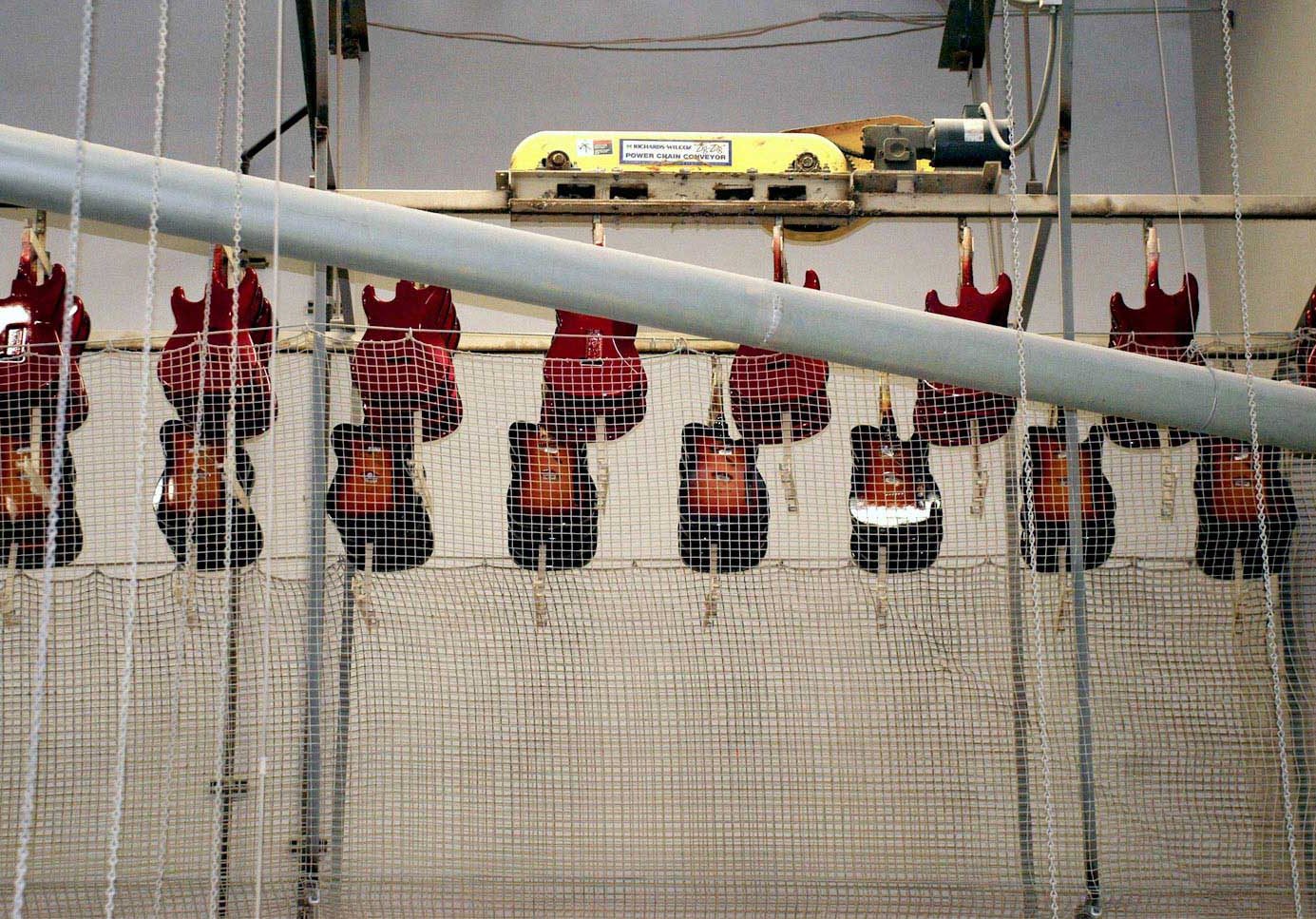

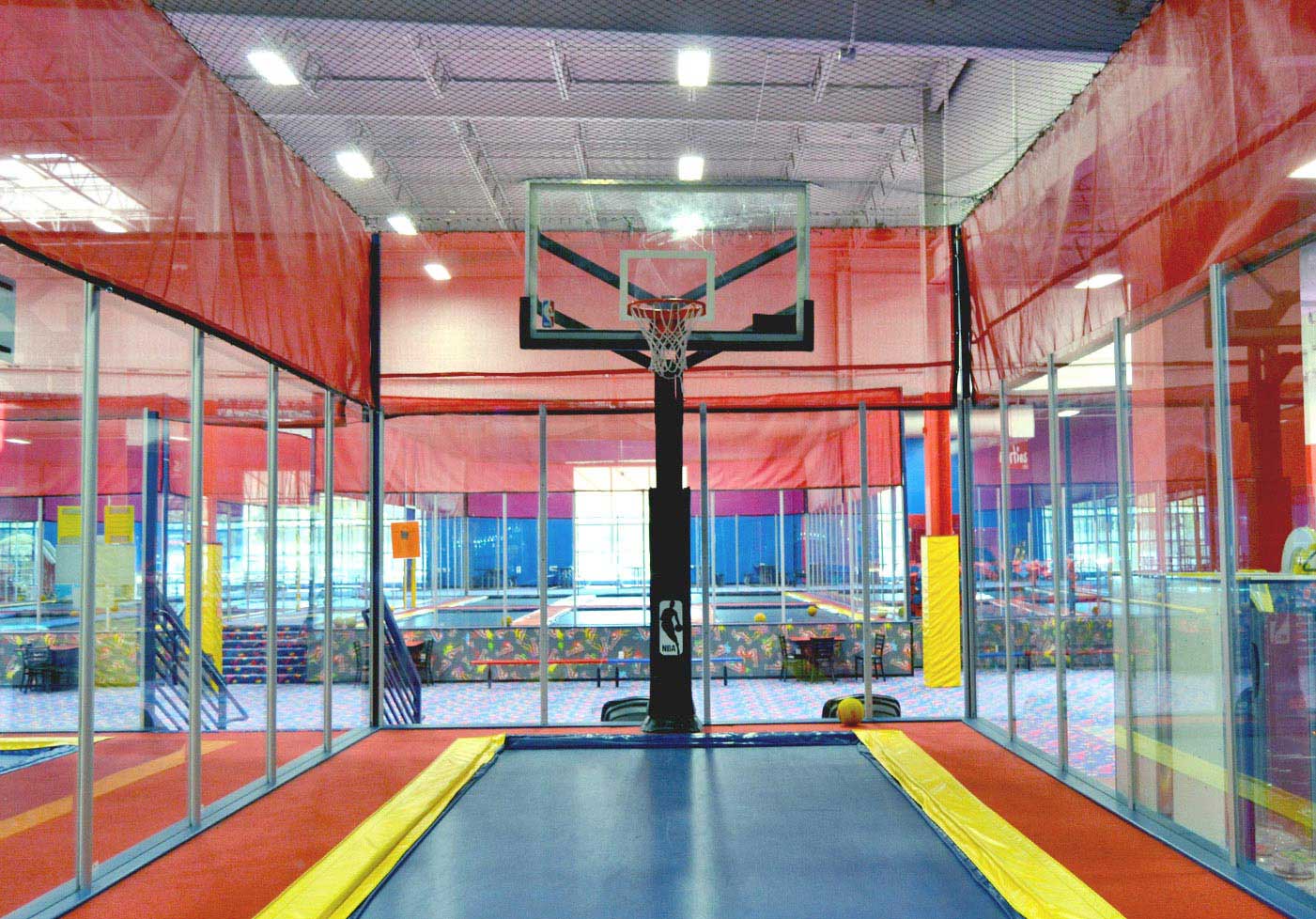

Safety netting can often be the first line of defense against the two most common causes of death on construction sites – falls and being hit by objects. Last February, we reported how OSHA expanded its allowable fall protection options to include netting for all “walking-working surfaces.” The standards set for industrial settings came mostly from the construction sector. Our construction netting solutions can dramatically improve the safety of your construction site and adhere to all OSHA rules and regulations.

Additionally, Pucuda Leading Edge is proud to support and work with ASTM. This internationally acclaimed and credited organization works tirelessly through its 30,000 members to improve the lives of millions every day and have developed countless standards for a safer world.

By keeping much of our focus on safety, Pucuda Leading Edge will continue to encourage a strong safety culture, not only at our company but at the jobsites we serve. We’ll always be intensely interested in how to improve safety on the job with our netting products. If you have a safety issue that could be solved using nets, feel free to contact us to speak with a netting specialist.