Safety Starts with Design

Over the expanse of my career, safety has made many changes. An evolution that started with a few contractors that required hard-hats progressed to all employees being safety savvy. This is something that was long ago adopted in the industrial sector and is slowly coming to the construction industry.

The lesson that many contractors are learning and have learned is that safety is important. The next step is for the construction industry to learn that safety can and should be a profit center. Many contractors, owners, GC’s, and CM’s are learning how OSIPS and CSIPS provide better control and benefits when it comes to managed risk. They are learning that a well-run project provides the benefits of lower loss costs, faster completion, and a benefit of dollars back for a well run project.

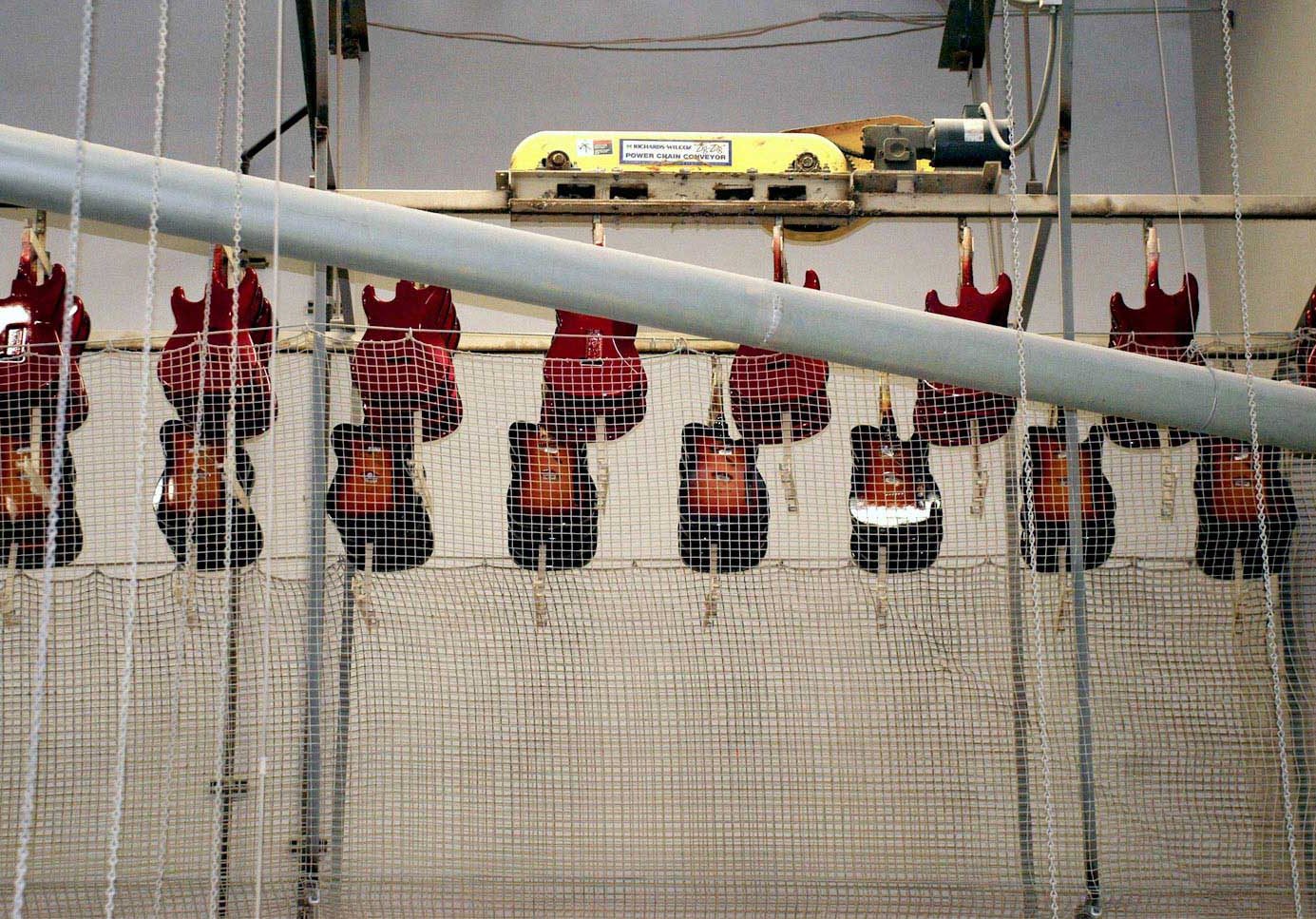

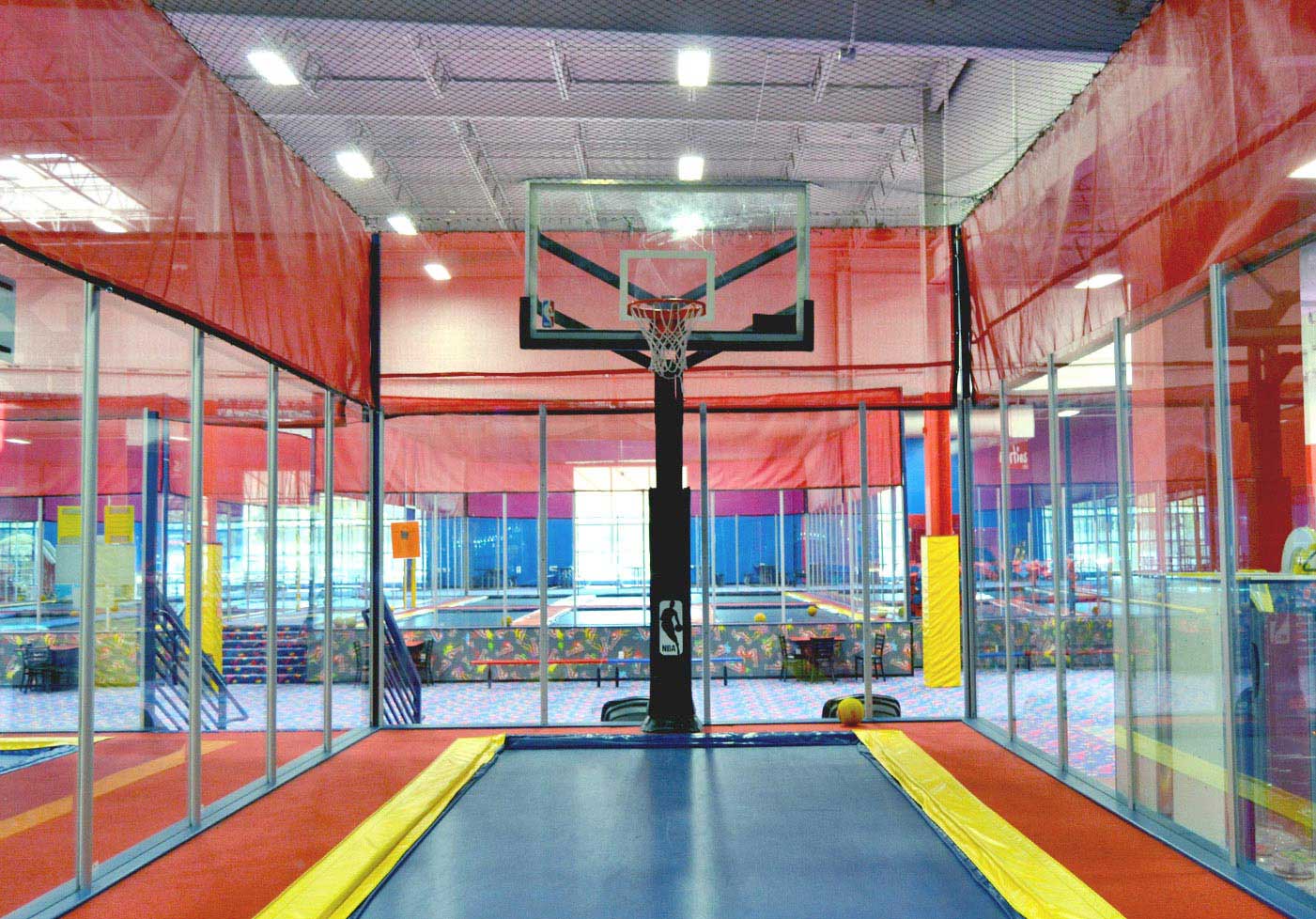

The cost of safety is always going to be there, but by making safety a planned area, starting with design, reduces redundancy and allows for better cycling of trades. Safety nets have always provided wrap up safety, but taking advantage of that has been sorely missed. One properly planned netting system can protect the trades working above, separate a trade below, such as window wall installation, and allow trades to cycle in a much more efficient manner. The huge benefits to the community by the implementation of safety and netting systems are also being realized. When you provide plans to protect neighboring properties, the project starts with good-will. Even the uneducated in construction notice safety and the expense of managing problems is minimized.

Netting systems have been the best kept secret. One would wonder how something that makes so much since is so over looked. Well it is the fault of the safety industry as a whole. We as an industry have failed to inform and educate the construction industry. It has long been a proven fact that passive safety increases productivity and that quickly translates to savings. So why, when OSHA has long realized that nets are an excellent if not preferred means of safety, don’t contractors utilize it more? I think it is as basic as the fact that the first thing that comes to mind is tying off workers, but there are many cases where that is not the best form of safety and can provide a huge weak link and a management nightmare. We as a construction industry have to police our workers to make sure they are even doing it, and then just the one second that they fail to tie off correctly, the accident happens, but netting, by virtue of being manufactured and installed correctly, provides full fall protection with a loss history of near zero.

Liability, which is something we all have and no one want to take, is the big scare, and so it gets forced down the throat of certain trades, then passed along so each trade becomes responsible for providing their own protection. At the end of the day, that translates to more cost to owners, slower builds, and duplication of costs passed along. Every day I work with contractors to help them to realize these savings and show them how to combine the fire-proofing tarps with the cycling of nets, provide separation in shafts while making it easy for installation of elevators, protect the public and the individual trades, and provide fall protection all in one. Three or more trades and PR are all protected for the cost of one system.

Leading Edge’s safety development is on the sites resolving the safety problems by making something that does, and should, provide a monetary return, in addition to just doing what is expected or required.