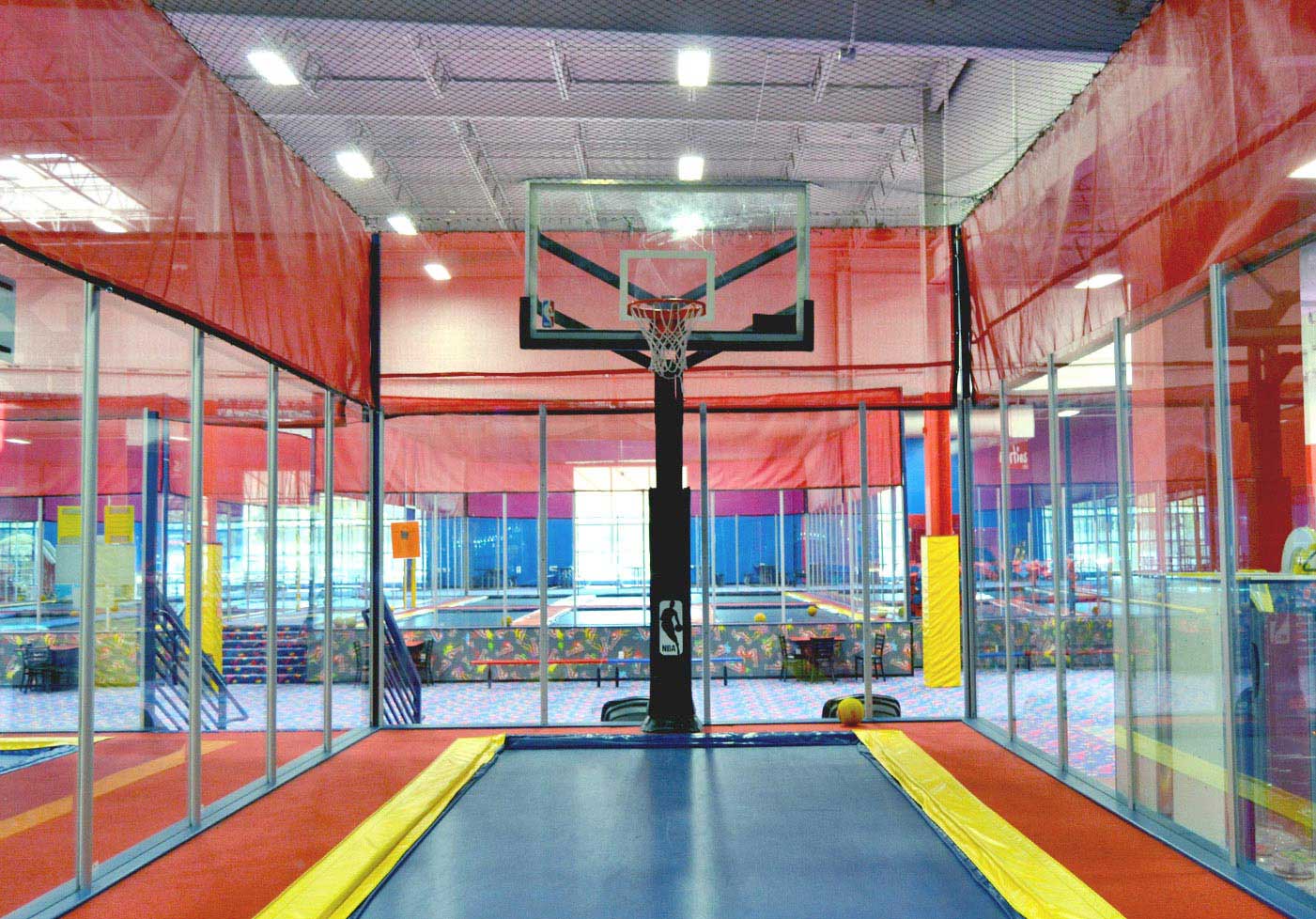

A net properly performs by both decelerating and catching a load. The type of material, method of manufacture, and technology used are vital components in determining how the net(s) will perform. A net cord or other component with a higher break-strength should not be assumed to make a stronger net. In fact, the stretch and other factors could make the capabilities of the net lower in a net manufactured with a higher break strength cord.

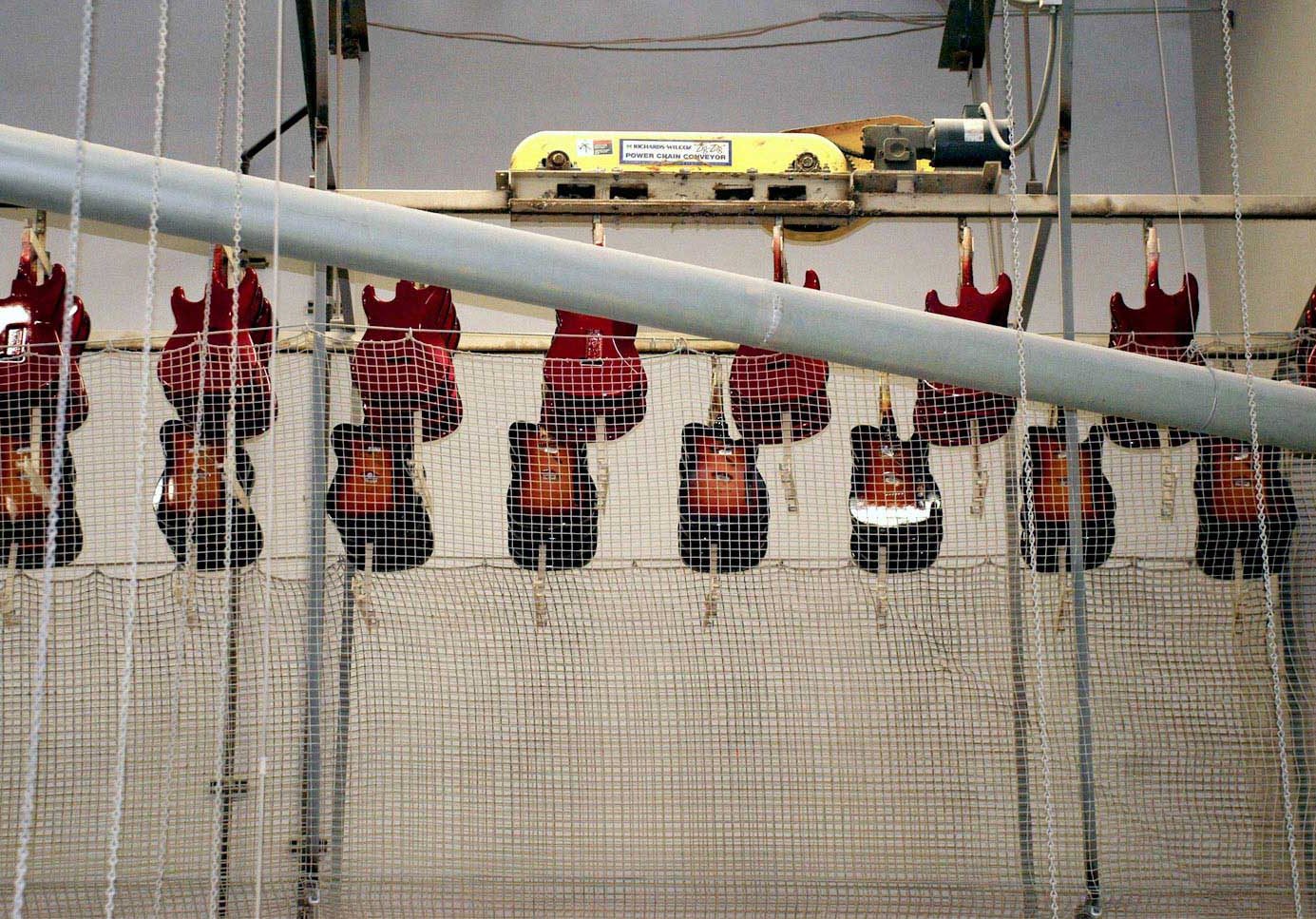

Many of the netting solutions that are offered come from the fishing industry and are marketed for safety as an off-shoot market. While they may be great for catching dinner, they don’t assure that the protection provided will bring husbands, wives, and children home for dinner. The construction methods are often antiquated and are designed for controlling catch size, not for catching or containing loads. Additionally, the construction is driven by supplying a cheap product in mass quantities. This leads to inconsistent controls over production methods, materials, and etcetera.

It is vitally important to incorporate the most advanced procedures, materials, and methods into netting system designs. The latest developments in netting have been made to ensure safe products and systems for the use in the modern safety world.

Years of working on countless projects has proven that a well planned and executed netting solutions provides optimum protection for all phases of the project. Leading Edge maintains the highest level of services by using engineers, field personnel, and technical representatives that are specifically trained for netting. As many engineers are aware, this is vital, due to the lack of available data for netting and netting systems. The planning for all conditions and methods of installation has proven to substantially reduce costs.