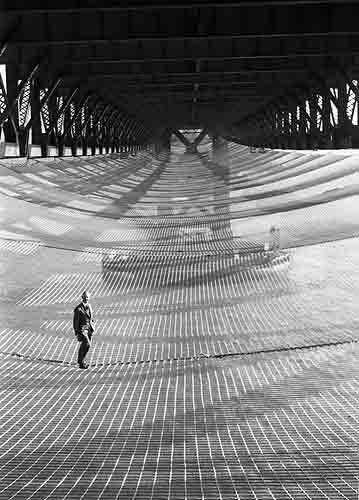

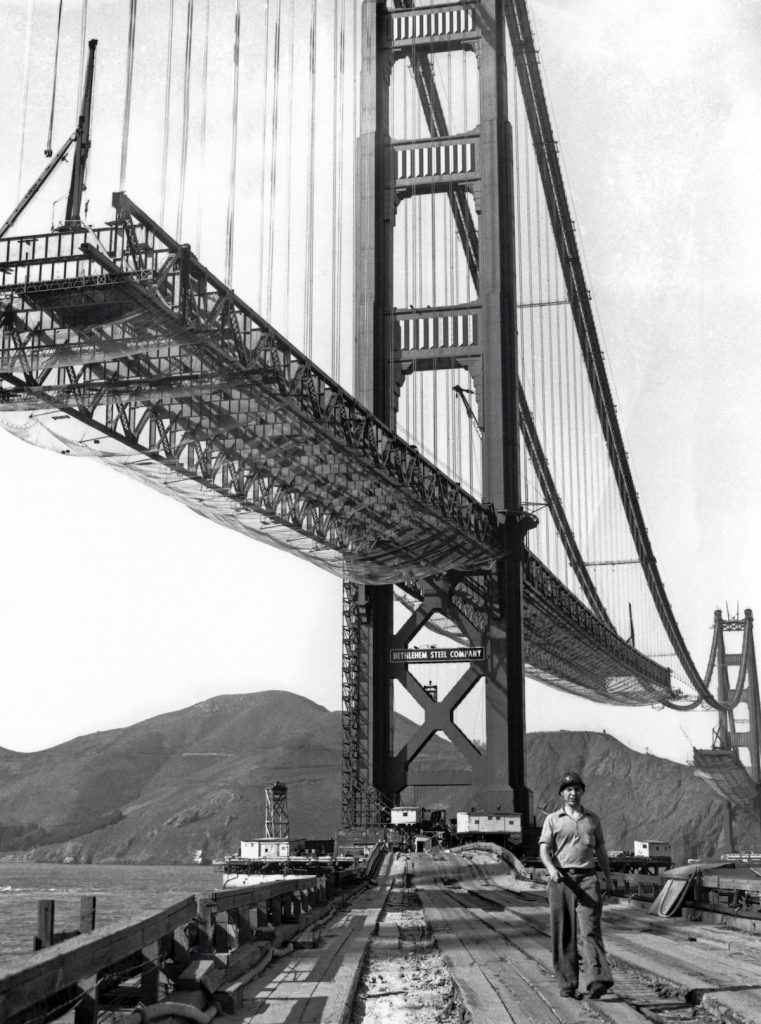

There is a long history of using safety netting on construction sites, but it hasn’t always been that way. It wasn’t until mid-way through the 20th century that the first instances of fall protection netting were used on construction sites. The first large scale use was during the construction of the Golden Gate Bridge, where safety netting was hung underneath the entire span of the bridge during construction.

Since then, there has been a gradual evolution of safety standards: which (unfortunately) were often a response to a tragic death or injury associated with a construction project. When OSHA was established in 1971, it was the result of decades of accidents which could have been prevented if there had been safety regulations which were required at the federal level. To this date, hundreds of injuries and deaths have been averted through the use of passive safety netting systems.

Why is passive safety the best way to protect a construction jobsite? Because human beings are fallible and accidents happen all the time through carelessness and poor decisions. The problem that occurs is that certain manufacturers are distributing horizontal safety nets systems which fail to meet the standards as set by ASTM, ASSE/ANSI, OSHA and The Army Corps of Engineers. In short this is what people are entitled to know about a safety netting system.

Why is passive safety the best way to protect a construction jobsite? Because human beings are fallible and accidents happen all the time through carelessness and poor decisions. The problem that occurs is that certain manufacturers are distributing horizontal safety nets systems which fail to meet the standards as set by ASTM, ASSE/ANSI, OSHA and The Army Corps of Engineers. In short this is what people are entitled to know about a safety netting system.

- Workers and the public should be informed if a safety net system does not meet all industry standards and regulations.

- Workers have a right to be trained and advised of the possibility of serious fall or impact injury because of cable and support locations.

- The public has a right be protected from falling debris that could be deflected or miss the nets.

- Safety netting systems should meet industry standards and have a proven safety record.

- A netting system should provide safety to workers above the nets as well as below them and to the public at the ground level.

- The competent person is responsible for knowing all of the standards, regulations, and laws. Any failures of safety protocols can result in litigation, fines or financial compensation.

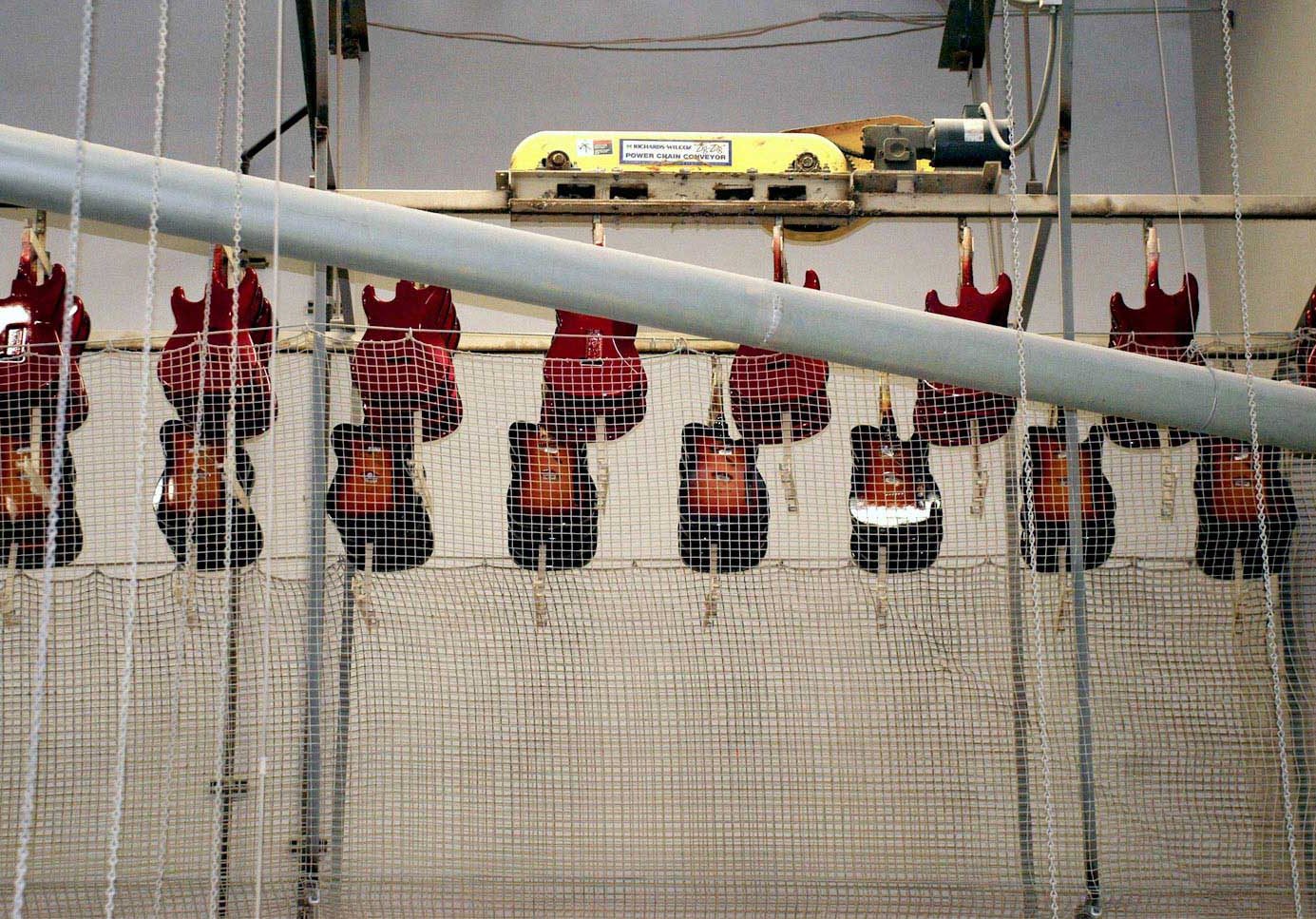

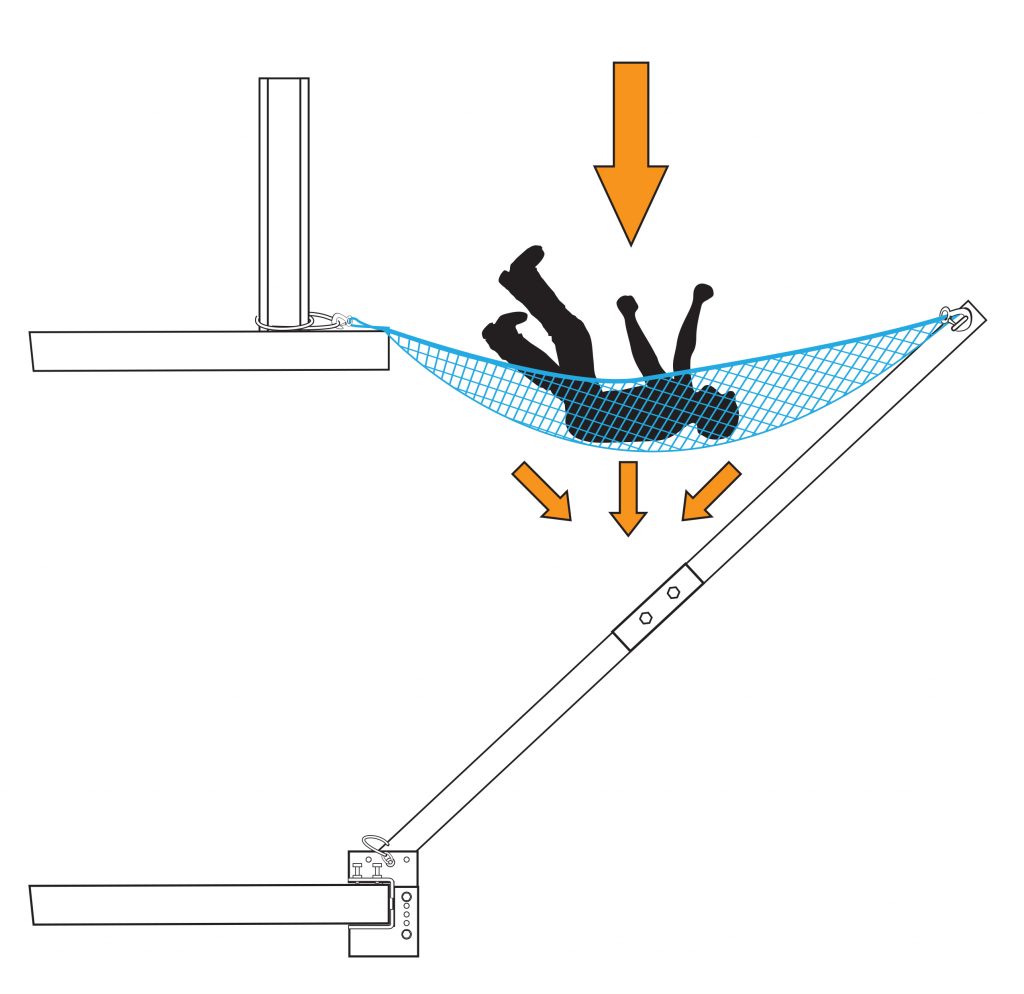

Fig. 1

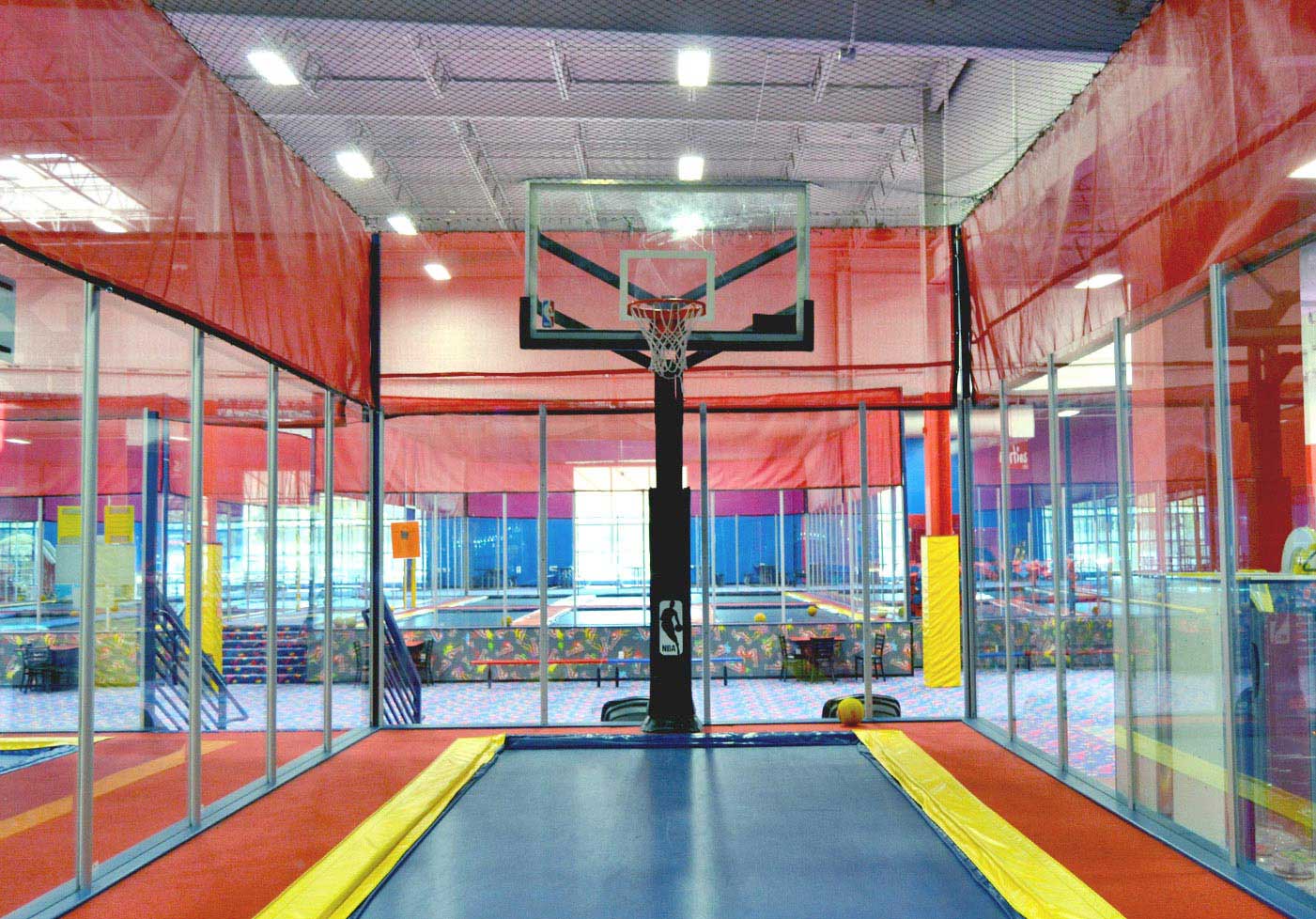

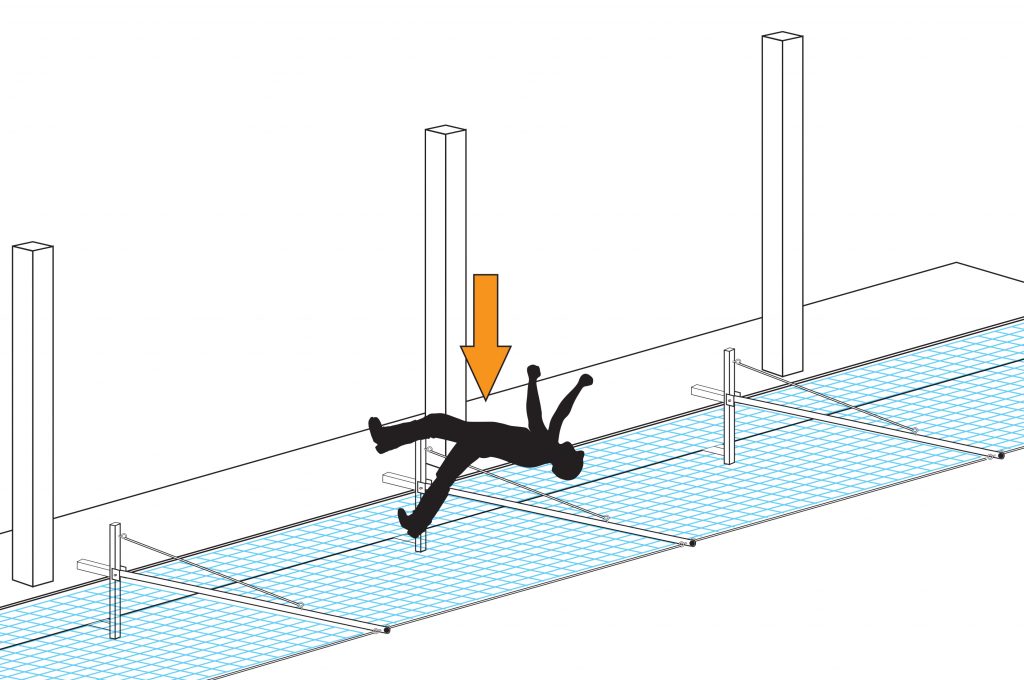

Fig. 2

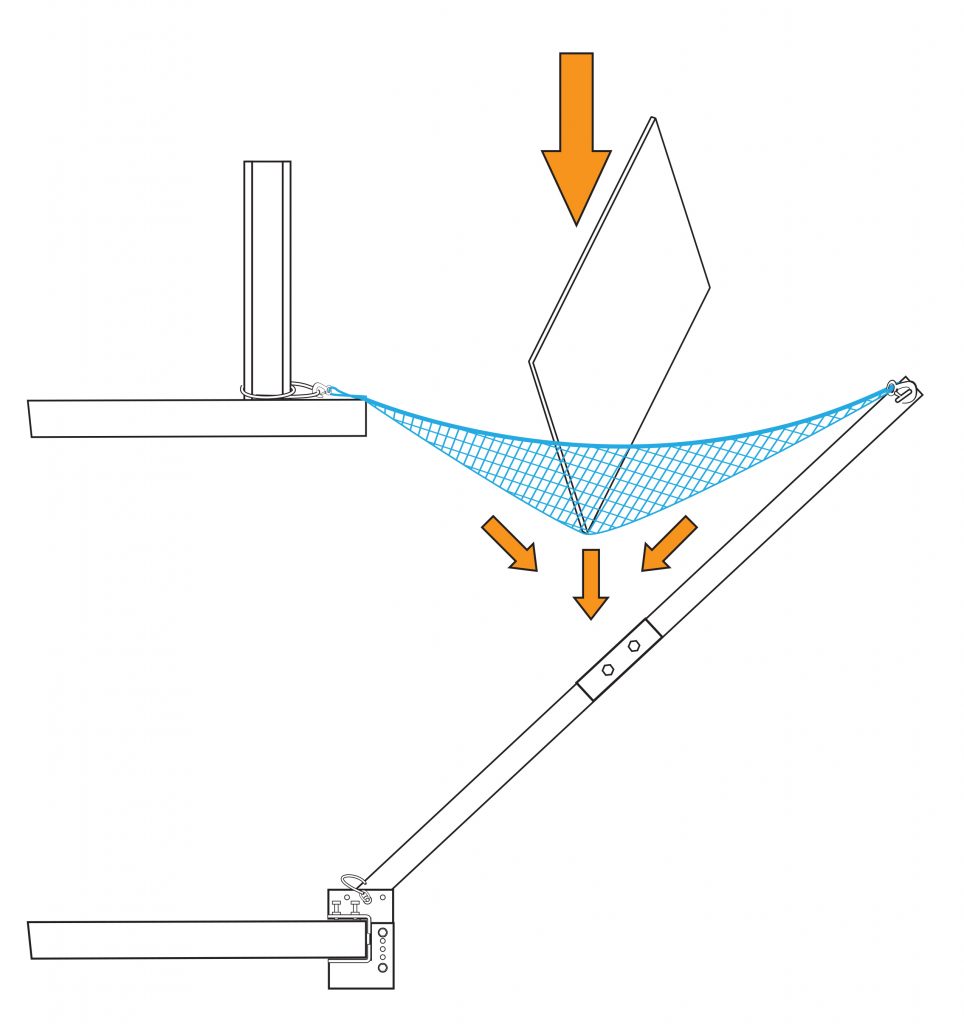

Open exposed edges of buildings allow all types of things to fall off a building. Keep in mind you have multiple trades and many workers working on a high-rise building while the floors are still open and exposed. Most debris and exposure comes from the top floors. A properly designed system catches the Load by Deceleration and a soft catch: free from supports, cables and obstructions that can be hit by a falling worker or falling debris (See Fig. 1 and Fig. 2). Here are a list of requirements that a properly designed perimeter safety netting system should meet:

(1) 17,000 ft. lb. prototype tested and manufacturer’s labeled net in it.

(2) Supports that are below and cannot be impacted by persons or debris.

(3) It is compliant when installed within 30 ft. of the working floor.

(4) The nets must extend out a minimum of 13 ft. Or it must be limited to protection less than 30 feet from the working surface as defined in the standards.

(5) The system design must pass a test with no significant residual distortion of the net pattern or the suspension system. The required test is a 400 lb. bag of sand dropped from 30 ft.

(6) A competent person shall inspect each construction project” “where potential for falling debris exists and threatens persons or property.

Fig. 3

Fig. 4

If your project doesn’t seem to meet these straightforward requirements, you most likely have a non-compliant system on your construction site (See Fig. 3 and Fig. 4).

We have produced a Technical Paper which examines the issues involved with safety nets and perimeter safety netting systems. You can go to this link and download a copy.

https://netting.com/resources/good-perimeter-safety-is-no-accident/

Pucuda Leading Edge provides safety netting for fall protection and debris containment netting. They provide assistance to both owners and contractors through consulting, engineering, and installation assistance.